Cup of Joe 42# - Dealing with CAPA

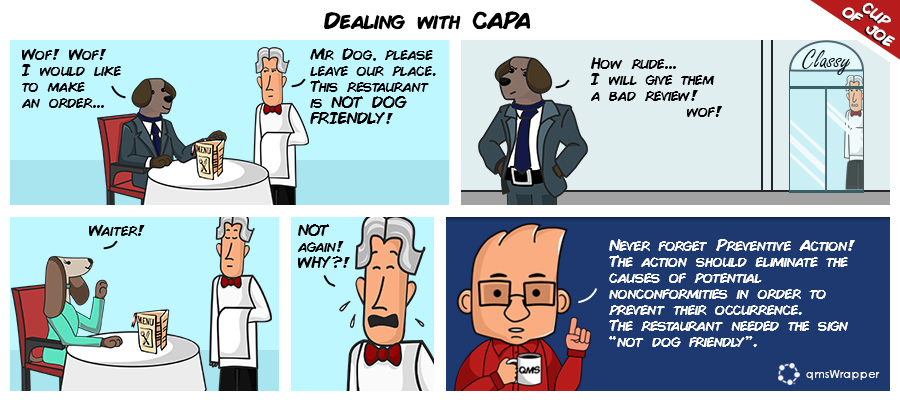

CAPA is a system that consists of improvements taken to eliminate the causes of non-conformities or any other undesirable situation within an organization’s process.

CAPA importance

Every company should develop a strategy for CAPA as part of its overall quality system.

To manage the suitable CAPA activity, it is important to track, manage and evaluate all different quality data points within the organization, and to manage key performance indicators throughout the process.

CAPA during the audit process

During the audit process, CAPA is always in the center of attention, and auditors are very strict when it comes to it. Also, failure to stick to proper corrective and preventive actions is considered a violation of regulations on good manufacturing practices.

First, auditing the procedure is carried out, then evaluation how it is implemented in practice.

During the audit process, auditors like to see all documentation that applies to CAPA process, to check complete traceability to root cause of the problem and verification of CAPA effectiveness, therefore it’s a good solution to keep all necessary data in one place where can be connected all the steps of a process.

It’s also important that your CAPA procedure is risk-based. It should be monitored, measured and there must be a report of the process effectiveness.

Consistency in dealing with CAPA is important since it is initiated to identify the root cause of nonconformances and to prevent reoccurrence. Not only that, it’s what Auditors expect.

In short, the CAPA process is here to serve us in continuous improvement, and to do that, the right tool such as eQMS is needed to enable a smooth process and all the benefits from CAPA.

Sonya

|

And it is true, PA is very important. In my former company, it was just something that they "needed to do". I hated it. And the software that we had one day just mixed all the information. Don't know what happened. After that situation, we needed to do more research to find a better program for us. We came upon qmsWrapper, started using it and no more problems. :) Now I am at a different company, but I miss using Wrapper. We are not producing a medical device, but I explained to my superior that it can be used for implementing different standards, not just iso 13485.