The qmsWrapper Story

Hear about qmsWrapper's Fascinating Transition from Medical Device Research Company

to the Most Successful QMS Software.

Learn How the Need for Efficient Collaboration and Compliance in the Medical Device Industry

Led to the Creation of qmsWrapper.

Follow it as it develops through a number of releases, each one jam-packed with useful tools for

simplifying quality control, document control, risk management, and other tasks.

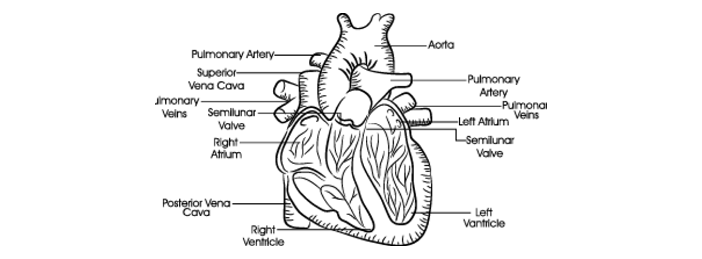

Our pedigree is as a medical device research company creating new medical technology related to heart health since 2018. We have offices in both North America and Europe. Some teams worked on the software, others hardware, with several medical teams involved in research at various hospital centers. We needed to communicate, coordinate and collaborate on the same tasks, events, and projects. Time zones were killers.

At first, we communicated through email but this was disjointed, chunky, and very inefficient. Ping-pong is a fun game, but not when played with email. We could not deal with issues in an interactive way, except by telephone - phone companies loved us, but the feeling was not mutual.

Then came Skype, which at first was a blessing but soon we realized a lot of work was lost as conversations and files were being saved in Skype, but not being saved in the related projects or tasks. Cut and paste became a burden and in the daily churn, it soon became a sporadic practice – impossible to enforce.

It was soon very obvious that Skype was really a social media tool with grim limitations.

Compliance was a nightmare, a paper layer to add to our daily woes.

We needed something that helped us work together, on the same files, on the same projects, live. There were many apps and project management software we used, and admittedly it helped! Still, it was disjointed, cut and paste remained the norm, and email was the rule. History was being lost.

Compliance was difficult and an increasing number of dedicated people were needed to overlord an unwanted system.

In desperation, we resorted to developing our own API-driven custom modules that ‘sort of' worked, at least until the next release of that application, then again a re-do.

And there was always a learning curve. It was never smooth; it was never easy. It was never natural.

Yet we persisted, compliance was a beast not to be denied or ignored.

After we received our first FDA clearance, we did an internal review and were shocked to realize the amount of time and effort it had taken to produce the mountain of paperwork required with respect to compliance and related to Quality Assurance, QSR, as required by FDA.

And then we applied for ISO13485 certification. TÜV, the German juggernaut of ISO certifications, insisted on seeing the paperwork from each location, at each location. But with a distributed team such as ours, located in so many places they insisted on several Business Class Tickets, 4 weeks of 5-star hotel stays limousine service, and a daily food budget equivalent to the GDP of a small country, just to review our ISO compliance documentation in situ.

We told them to take a hike… Europe and ISO13485 would wait.

We realized right then that we needed a better solution.

The TUV’s of the world don’t understand quality in motion, quality as a process rather than as an end result - a piece of paper. They didn’t understand that quality drove workflows, and was executed at all levels within a relatively flat management structure where everyone is responsible for the quality, at every step. Quality that should embody collaboration and compliance, not drive paperwork.

We needed to rethink our approach to Quality, to Compliance.

We needed something where Quality was not an afterthought, but something built into the DNA of our workflows. It had to be anchored in collaboration and supported in our daily processes on an ongoing and continuous basis, not in monthly or quarterly reports.

Our Eureka moment, was when we realized that compliance could be managed through quality.

And so it began, as our clinical investigations unfolded over the next year, part of the SW team was dedicated to developing our own quality & compliance app. It was for us, something we could actually use, something we could actually believe in.

And collaboration became a way to work all the angles of compliance, with quality.

The heart of Wrapper is its integrated approach to Quality Management Systems (QMS). Projects, tasks, documents, events, CAPAs, etc all integrate into the QM system, not separately but interactively, and collaboratively.

If a process has an ISO angle, it can output the right report at the right point in time. If a management review is required, it is initiated, and automatically agendized... (new word). If follow-up action is required, it is automatically scheduled forward into a new task and placed in the next QM review.

But because QMS is at the heart of Wrapper, it is not an “added layer” of bureaucracy.

Being integrated means that QMS is integral to everyone’s project tasks … with minimal impact. A minute here, a minute there is nothing to each user, but when accumulated it makes for a highly effective collaboration system by which to manage through quality, not manage the quality. Quality becomes a pervasive collaboration in the everyday.

We were excited at how it was transforming our culture.

Then, traveling from San Diego to Toronto, I was talking to a software product manager for the insurance industry. We compared notes and then the topic of Wrapper came up, and Babam! She immediately demanded my business card and insisted her manager would call me the following morning. They were suffering from the same pain as we were and in her words - they desperately needed this!

At 9:01 am, the next day, I got the call.

I knew right then, that this was destined to be something great…

Now, WE cannot live without it.

Since our first public release in 2019, qmsWrapper has continuously evolved into a powerful, risk-driven QMS. Each milestone reflects our commitment to simplify compliance, support medical device companies, and enable audit-ready quality management.

- 2019 – First public release. A complete ISO 13485 QMS with Project Management, Document Management, Risk Management (ISO 14971), and collaboration modules. Delivered with a full set of SOPs, workflows, templates and fully Validated for FDA and ISO compliance.

- 2020 – Introduced the Interactive Quality Manual Creator and Gap Report Tool, fully aligned with ISO 13485:2016 and FDA QSR (21 CFR 820).

- 2021 – Added the Traceability Matrix and an upgraded Risk Module, supporting medical device companies in preparing 510k and CE Mark submissions.

- 2021 – Major integration with Jira. Core functionality evolved into an enterprise-grade Processing Engine.

- 2022 – Expanded to support ISO 9001:2015, making qmsWrapper valuable for any organisation implementing a QMS.

- 2022 – Launched the Wrapper Desktop App, QMS Tags, enhanced system notifications, and beginner-friendly SOP Templates and Workflows tailored for MedTech startups.

- 2022 – Major UI redesign and 6 new modules: CAPA, Nonconformity, Training, Change Management, Complaint Management, Supplier Management.

- 2023 – Delivered an MDR-compliant Quality Manual and connected ISO 13485 templates to support the transition from MDD to MDR.

- 2023 – Launched WrapperApp for Document Management with online editing, revision control, and Wrapper Storage Cloud sync.

- 2024 – Introduced a redesigned Form Dashboard, quick-access meeting tools, direct process initiation from forms/files, and deeper risk integration.

- 2025 – Released the Event Log (for Changes, Deviations, Nonconformities, Feedback) and the Hazard Log aligned with ISO 14971 and MDR. Added Unified Forms and automated Actions for a truly risk-driven QMS.

We help our customers not just to achieve and maintain Standard Compliance, but to reimagine their businesses too, this is what drives us. Our vision is to guide our customers through a journey of growth and business transformation with our qmsWrapper solutions and services, helping them become leaders in their industry and suppliers of choice.

We will continue to develop and deliver solutions that are the right fit for our customers. Everyone in the business takes our customer's goals and objectives seriously and understands that our success is driven by our customer's success and the valued partnerships we have created with them.

Come share our vision.

The qmsWrapper Team